What Are The Different Printing Methods Available?

There are many different types of printing methods available and they’re continuing to evolve. Each type is suited to a different need, meaning that businesses can choose a printing technique that best highlights their products or service. So what are the different types of printing and how do they vary from each other?

In the textile and garment industry, which printings are commonly used?

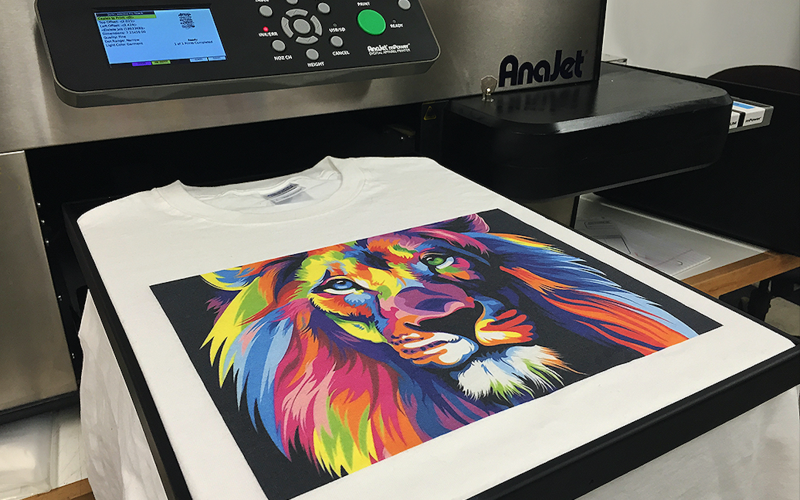

1.Digital Printing–数码印

The Chinese translation is “数码印”, please take note of it.

Custom Products

T-shirts, hoodies, phone cases, mugs, laptop sleeves ,and more.

Digital printing is a modern method that covers a variety of different techniques including inkjet printing and laser. In digital printing, images are sent directly to the printer using digital files such as PDFs. This eliminates the need for a printing plate, which is used in other types of printing such as lithography and can save time and money (unless you’re printing in larger numbers).

Eco-friendly Products

Products made from, or with, sustainable materials & methods.

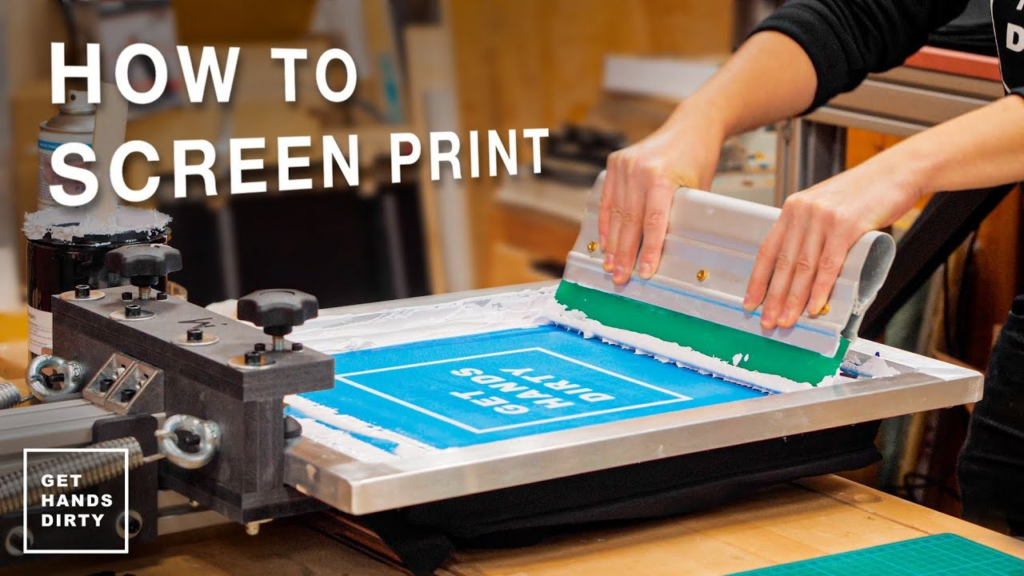

2.Screen Printing–丝网印

PREPARING ARTWORK

To print a shirt, you of course have to have something to print on the shirt. Whether you design the artwork yourself or a customer brings it to you, all screen printing starts with some type of artwork. When thinking about the artwork you want on your t-shirts, remember that garbage in equals garbage out. In essence, the better the quality of artwork you start with, the better quality of a screen print you end up with. When screen printing t-shirts, you print one color at a time. If you are printing multiple colors, you will need a way to separate the colors from each other so you can create different screens for your design. You need one color per screen.

A lot of screen printers use Illustrator, Photoshop, or Procreate to take care of their artwork needs. These programs separate and clean up the artwork to help you prepare for printing.

PRINTING FILM POSITIVES

Once the artwork is created and the colors are separated, the next step is to print a film positive. A film’s positive transparency is basically like overhead transparency. You will use this film positively to burn the image into a silk screen. Whatever you want to print on the t-shirt, you print it out in black ink on the film positive.

There are 4 main differences between Screen printing & digital print.

- Digital printing is an environmentally friendly printing method for new industries, while screen printing is a traditional printing method, which is even less environmentally friendly. There will be washing water.

- There is no color registration limit for digital printing. It is based on the basic color that is controlled by a computer to generate thousands of colors. And screen printing does have color restrictions. It can only print a single color at a time.

- The digital printing process is simple, and map printing is just fine. The silkscreen must first use digital printing film, and then make the silk screen version by the film. Print another color.

- The color of digital printing is richer and more layered, and 3D renderings can be printed.

3. Discharge printing—白墨印

Discharge printing is the process of using water-based inks to bleach the manufacturer’s dye out of a shirt and replace it with whatever dye color you choose. This kind of discharge screen printing is done with water-based inks that soak into the fabric, instead of just sitting on top of it.

Discharge printing is a way to remove the shirt’s color and replace it, instead of putting ink on TOP of the shirt.

The result? Super soft prints that are part of the shirt. Awesome.

What Is Discharge Printing?

Discharge printing is a screen printing process where the same techniques and equipment are used but instead of normal ink, discharge inks are used, which remove the shirt’s dye instead of putting a color on top of the shirt. It is somewhat similar to bleaching in a design, except it doesn’t damage the fibers like bleaching would. It results in an extremely soft print and shows the weave of the shirt.

It can be used by itself, as an under base for other colors to be put on top, or with pigments added.

Pigmenting discharge can be difficult to achieve exact color results, as the discharge efficacy affects the color, and what you see is not what you get when mixing the pigments, but it can still be a great way to achieve colors on dark garments.

4. Puff print—泡泡印

What is a puff print?

Puff ink is not actually an ink – it’s an additive, stirred into plastisol ink before printing. When it reaches around 320 degrees Fahrenheit, the flat print “puffs”, creating a 3d embossed texture that rises above the rest of the fabric.

Does puff print last?

Does Puff print last as long as normal ink when used for t-shirt printing? Puff ink will last as long as our regular water-based inks if your garment is cared for correctly.

5. Plastisol Print–胶印

What is plastisol print?

Plastisol printing is the traditional style of screen printing. This ink creates a design that sits on top of the fabric for a traditional look and feels. These inks can be used on any garment or fabric and work best in small print areas.

Does plastisol work on polyester?

Plastisol ink will adhere to polyester substrates without the aid of catalysts or additives. The introduction of catalysts or additives will reduce the bleed resistance of the ink. Polyester garments will bleed unless printed with pure bleed-resistant inks.

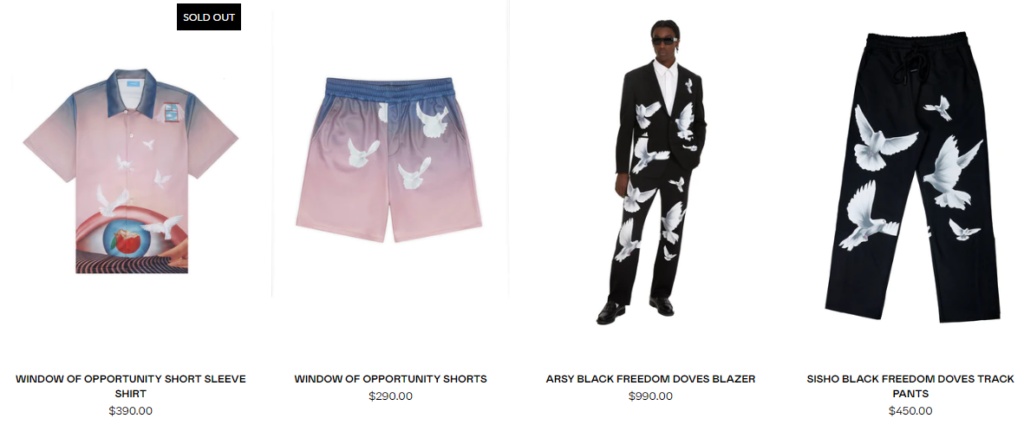

Fashion Brands that our factory cooperates with

Are you looking for an all-rounder factory? Help you solve the one-stop clothing supply chain problem?

Please feel free to contact us, we will bring you a 100% satisfactory cooperation experience.

Looking forward to our next cooperation with the brand is you!

please send an email to our brand manager:

we are waiting for you!